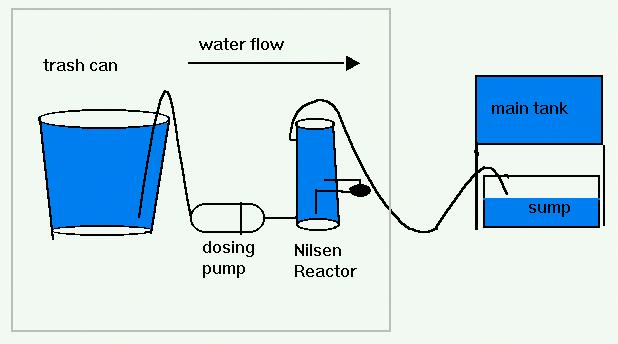

but I will give you some insight into the problems I encountered building it and as to it's performance. Below is a picture of my reactor in action. The differences in my version will be described below:

I seem to be getting lazier by the day. First I bought a pH probe so I wouldn't

have to keep checking my pH. Then I set up my two Tap Water Purifiers to output

into a 35 gallon can so I wouldn't have to make DI water once a week. Then I bought

a Reef-Filler top off pump so I wouldn't have to manually replace the evaporated

water daily. Then I started dosing b-ionic because I didn't want the hassle of dripping

kalkwasser. And now I've constructed a Nilsen Kalk reactor so I don't have to dose

b-ionic. The next step will be to buy a Lazy Boy Recliner to place in front of the

tank!

I'm not going to detail the plans as they are available on the Web at http://camelreef.free.fr/equipment/equipment.html#kalk

but I will give you some insight into the problems I encountered building it

and as to it's performance. Below is a picture of my reactor in action. The differences

in my version will be described below:

I suggest you also read the article

by Nicolas Will which explains why this method for dosing kalk is a good idea.

So let's start with the construction, or more accurately, the procurement of

material. The reactor body really needs to be constructed of clear tubing so that

you can see what's going on and when it's time to add more kalkwasser. The use of

4" clear PVC will allow for the easiest construction because it is physically

compatible with the PVC pipe fittings you will also need to use. The problem with

4" clear PVC is the price, figure on about $20/foot for it and you will need

2 feet. I found 4" clear acrylic tubing at Aquatic

Eco-Systems for around $9.75/foot. Acrylic is much clearer (clear PVC has a

blue tint) but is harder to glue. I found that for low pressure applications that

you can use Home Depot's PVC/CPVC/ABS cement and primer. I have my reactor located

about 50' from my sump on the same floor so even though the tubing does run both

above and below the sump level in it's circuitous route to my sump, the head pressure

isn't too much and I could use that cement. Be careful with the primer because it

will etch the acrylic if it's is dripped onto it, which is another indication that

the cement is creating a chemical bond between the materials. If your setup requires

high pressure than Weld-On #40 2 part cement is the ticket. Of course if you opt

for the clear PVC than regular PVC cement will work. I used a hacksaw to cut my

Acrylic tubing into 6.5" long and 13" long pieces

The second difficult item for me to find was the plastic tubing to be used in

the recirculating pump assembly. I could not find small diameter plastic tubing

anywhere near where I live so I settled for 5/8" O.D. (1/2" I.D.) CPVC

tubing from Home Depot. It was a little larger than I originally desired but ended

up working fine. Drilling the holes for the 5/8" O.D. CPVC was somewhat of

a problem. First off, I was lucky enough to be able to borrow a 5/8" drill

bit as the cheapest I found one for was almost $16 at Walmart. Next, be careful

drilling if you are using the acrylic instead of the PVC. Make sure the glue is

thoroughly cured and go very slow. If your drill bit is new consider dulling it

a bit by drilling into some steel first. You will find that you cut right through

the PVC but going through the acrylic is another matter. Go slow, in short bursts,

and cool it with water if you can. Also, be careful not to elongate the holes in

the PVC while you're drilling through the acrylic. Since we are talking about the

recirculating pump assembly , I used a Maxi Jet 250, 67 gph power head, and restricted

the input by almost 50% to slow it down even more. The object of the recirculation

pump is to stir up the kalkwasser without causing it to mix in with the upper saturated

(clear) portion of the reactor reservoir from where the output effluent is drawn.

I felt that the brand new maxi jet was just a little too powerful and hence I restricted

it. The pump only has to be run a few minutes at a time 4 to 6 times a day so this

should not be a problem in the long term.

Next were the 4" PVC pipe fittings, all of which were procured at Home Depot.

A standard 4" slip coupling, a domed end cap, a clean-out cover and thread

collar, and a toilet closet plate to use as a stand. As suggested in the plans,

I cut the end cap leaving about 3/4" for the gluing surface, and used the part

I cut off to glue to the closet flange, and then to the end cap, to form a stand.

You will have to bevel the piece cut off the end cap to enable you to have enough

contact area with the end cap for a strong cemented connection. The slip coupling

and clean-out collar were attached unmodified but I should speak a little more about

the clean-out. I really wanted to find a cover which had a o-ring seal like the

one that is depicted in the plans but couldn't find one. The clean-out does work

but I have to use 2 or 3 layers of teflon tape every time I close it in order to

make a good seal. Another modification I made was to drill a hole and glue a piece

of rigid airline tubing to the center of the clean-out cap itself to create a nipple.

Attached to the nipple is a piece of flexible airline tubing and a plastic air valve.

Since this is the highest point in the Reactor it is used to bleed out any air trapped

when you replenish or service the reactor and to bleed off pressure when you are

about to open it. A reminder while I'm talking about opening up the reactor, don't

forget to insert a check valve in the outlet line so that when you do open the reactor,

all the water in the output tubing and sump doesn't come rushing out all over the

floor.

The last modification I made to the design was the water inlet and outlet to

the reactor. Since my Reef-filler used 3/8" I.D. tubing I wanted to make the

inlet and outlet that size. I also did not want the nipples for them to be on the

cap as in the plans. What I did was purchase 2 polypropylene 90 deg 1/2NPTx3/8"

barbs. I drilled and tapped a hole in the side of the clean-out collar for the output

and the side of the bottom end cap for the input. These locations have worked fine.

You can also find the barbs in larger or smaller sizes to fit your need.

COSTS: Clear 4" Tubing (2 ft) $17(Acrylic) $44(PVC)

4" pipe fittings, cement,

1/2"CPVC(5/8" O.D.), barbs $22

Maxi Jet 250 $15

1/2"NPT Tap $7

hose clamps and

misc tubing $5

3/8" check valve $2.50

rigid airline tubing

and valve $4

_____ _____

TOTAL $65.50 $99.50

4" pipe fittings, cement,

1/2"CPVC(5/8" O.D.), barbs $22

Maxi Jet 250 $15

1/2"NPT Tap $7

hose clamps and

misc tubing $5

3/8" check valve $2.50

rigid airline tubing

and valve $4

_____ _____

TOTAL $65.50 $99.50

OPERATION:

I connected the input and output lines to the reactor and filled the chamber

with almost 2 gallons of DI water and 3 heaping teaspoons of kalkwasser. Next I

put teflon tape on the threads of the cover, wrapping the threads 3 times with the

tape, and then screwing on the cover. I turned on the Reef-filler just long enough

to bleed the air out of the reactor and then turned it off. Since the water in the

reactor was very cloudy caused by the initial filling, I let things stand for about

4 hours before turning on the system so I would not be pumping un-dissolved kalk

into my sump. I guess now is the time to talk about the mixing pump timer. The kalk

requires stirring about 4 to 6 times a day and really only for about 5 minutes each

time. I used a $5 timer I got at Home Depot for this purpose. I just happened to

have extra on/off tabs from my 2 other timers which I use for my lights so I was

able to get away with using a cheap timer. You will have to find a timer which allows

for at least 4 on/off cycles a day. The shortest duration that my timer will turn

on for is about 20-30 minutes so that's what I use, 4 times a day.

Once I turned on the system, it was a hands off operation. After a few days my

DKH was about 9.6 and Calcium was about 350. I then increased the amount of kalk

input to my tank by increasing the evaporation rate, and then adjusting the Reef-filler

to catch up with the new rate.

One concern I have is that the pH is up, ranging from 8.4x to 8.5x. I will keep

monitoring it and let you know if it continues to rise or stabilizes out.

PROGRESS: ** Updated 2/13/00 **

It's been about 2 weeks now since I started using my reactor. I'm a little disappointed

about the readings I getting but others who know more than I say that they are good

for just using kalk. My dKH is 9.8 and my Ca is 380-390 according to my Salifert

test kits.

As for problems with the reactor itself, the only annoyance is that as mentioned

earlier, the cap is hard to seal. Often times this means a few drops a day making

it to the floor. I've placed a plastic plate under the reactor to collect this excess.

I plan on trying Teflon paste as it's supposed to seal better and is also supposed

to be reef safe.

Also, I have not been able go get more than about 5 days before recharging, I

was hoping for a minimum of 7. I must say that I have not experimented much with

the amount of kalk I charge the reactor withàsomething I will start doing

next week. ** UPDATE ** I can now easily get 7-10 days out of the reactor. My next

goal will be 14. I think another spoon of Kalk will do that. This may all be for

naught because I've just ordered some pickeling lime, $1.49/lb vs $9/lb for kalk,

so I may be in for some more experimentation. I'll let you know how it works out.

pH continues to be somewhat high ranging from 8.30 to 8.56. I noticed that if

I recharge before it's time my ph increases a point to 8.4 - 8.66. It is possible

that adding more kalk before it's depleted and not letting it sit for a few hours

causes a more milky effluent to get to the sump. Or, it means I need to increase

the initial charge to better saturate the reactor, which may result in both longer

times between recharge and higher Ca readings. One installation task I performed

was to allow the output tubing fron the reactor to rise straight up to around 6

feet before turning and heading for the tank. This allows for 6 feet of settling

which I think keeps the undisolved kalk out of the sump. ** UPDATE ** It seems that

my pH meter went out of cal DOH! A recal brought my pH range between about 8.28

and 8.49.

Another thing I've discovered is that I can tell when it's time for a recharge

without looking at the reactor. All I have to do is look at my Pinpoint pH meter.

My pH will drop a full point when the reactor effluent drops below a pH of 12. So

if I get up in the morning and my pH is 8.20 I know it's time to recharge the reactor

and if it's 8.3 when I get home from work it's time to recharge. This means that

if you have an accurate way to measure pH you can probably get away with using only

plain white PVC in your reactor and saving the cost of the clear pipe.

*UPDATE*

Just thought I'd give you a short update on my Reactor. It's still working fine

and after almost 4 months of use I took it apart to give it it's first cleaning.

To my suprise it really didn't need any cleaning, nothing was clogged, no kalk buildup,

and most suprising was that the Max-Jet 250 powerhead was clean, and looked brand

new. The 4 months of use where it circulated the Kalkwasser solution 6 times a day

had absoultly no effect on the pump or impeller...cool

Also, I have switched to Mrs Wages Pickeling Lime with no noticable affects. Here's

what Craig Bingman has to say about it.

Craig Bingman wrote:

"Mrs. Wages is FCC grade (Food Chemical Codex) lime. It is probably as good

a grade as most of the calcium hydroxide on the aquarium market. The aquarium lime

products hold their sources and the grade used pretty close to their chest. ;-)"

"Since Ms. Wage's lime is seasonal in nature, by this time of year, it has

been sitting on the shelves for at least six months. So it may have absorbed some

carbon dioxide from the atmosphere by the time you use it. Conesquentially, when

I use food grade lime, I use more to be sure that I get a saturated limewater product.

Given how inexpensive the food grade lime is compared to aquarium lime, there isn't

much financial penalty to using a little extra."

"For that matter, one never knows how long that lime has sat on the shelf at

the fish store, either. One additional comment. The food grade limes that I've seen

appear to be A bit more coarse than the product from TLF. That meAns that the TLF

lime will dissolve somewhat more rapidly then the food grade limes you get from

the supermarket. That is a desirable property, especially if people want to mix

lime with minimal effort. As in they might prefer their limewater "shaken,

not stirred.""

"Because I found phosphate rejection more efficient when limewater was vigorously

mixed and then allowed to stand overnight, the particle size issue isn't that big

a deal for me, but it might be for individuals who go to lesser lengths to make

a saturated solution.

Craig"

http://www.viaweb.com/mrswages/mrswagpiclim.html

*UPDATE* June 00

I've switched back to ESV kalk in June of 00. As Craig states above, the lime is

more course that the ESV Kalk and because of that, I went through 2 impellers on

the maxijet in a couple of months since starting the lime. As I type this update

it is now 20 Oct 00 and the Maxijet wear is back to normal, which is no wear from

the ESV kalk.

*UPDATE* Nov 01

Reactor still working great. Using ESV kalk and current readings are Ca at 500+

and dKH at 13.6

Who said you couldnt use PVC cement :)